Even the most highly skilled sheet metal engineers can be prone to human error. That’s why our team uses the latest technologies and innovations in automation for our custom metal fabrication operations for business across Melbourne.

With our CAD/CAM software, our custom sheet metal machines can cut a variety of materials rapidly and with a very low margin for error, while also being able to provide the ability to receive custom-made prototypes for our customers.

Computer-aided design (CAD)

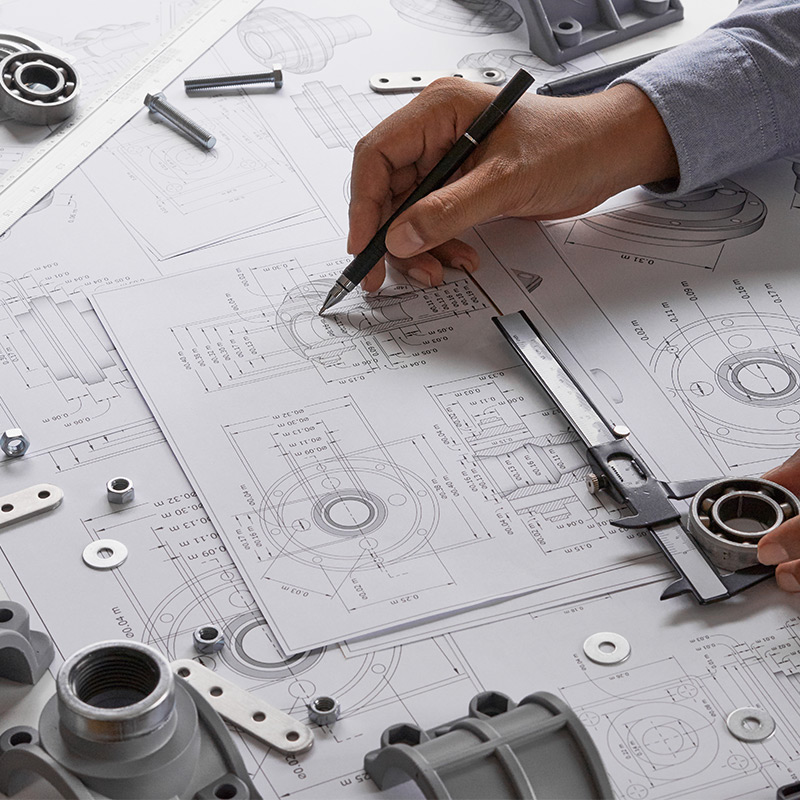

Before a single material is cut, the success of a custom project hinges on proper design.

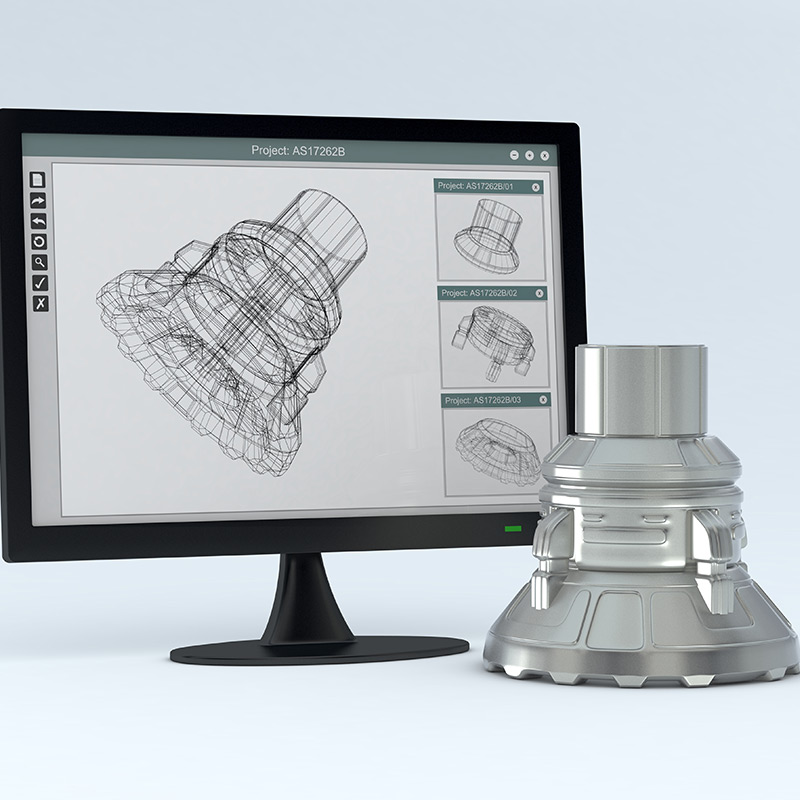

The use of schematics and blueprint has been superseded by powerful computer modelling. Our team has embraced this process. We implement specialised software such as SOLIDWORKS and AutoCAD to create 2D and 3D prototypes for the highest standards in fabrication.

Computer aided manufacturing (CAM) software

Along with CAD designing, we use the latest computer-aided manufacturing software such as MetaCAM and Metalix, allowing our machines to be programmed to understand and replicate every facet of a production design. Using CAM software for your manufacturing project delivers a range of benefits, including:

- Speed: Greater speed in producing custom projects of all shapes and sizes, including high volume work for construction and manufacturing

- Efficiency: Around the clock, automated operation that delivers greater efficiencies

- Complete accuracy and consistency: Every single version of the product created will be identical to the last

- Complex design: The ability to develop and follow complex designs that can be subject to human error

CAM requires a high level of expertise to operate. You can trust our highly skilled and experienced team to deliver the best sheet metal products using this technology. We offer the full suite of sheet metal design and fabrication services, all delivered to the highest standards.

Our team has a long history of providing the most reputable results across a range of services, including:

Perforations

Our manufacturing team has 20 ready-made metal perforation patterns. We also deliver custom projects to meet your specific needs. We use the latest AMADA turret punch machines that can press up to 30 tonnes, so no job is too big or too small.

CNC folding

Our team uses the latest CNC (computer numerically controlled) folding technologies for the most accurate and high-quality work. Your specifications are fed into the software, which then operates the machinery to deliver premium results in folding, laser cutting and punching.

We’ve established a reputation as a go-to CNC folding service for operations across Melbourne. We can accommodate mild steel, aluminium and galvanised and stainless steel in all sizes. This automated process delivers up to 250 tonnes in bending force and 4200mm bending length, with completely accurate finishes delivered under the tightest of deadlines.

For more information on our CAD/CAM services and custom steel fabrication in Melbourne, contact us on (03) 9706 4808 or email us your request to sales@knsmetals.com.au.

Make an Enquiry